Safety in industrial cleaning is a crucial aspect of maintaining a secure and efficient work environment. It may seem obvious, but it is not just about keeping spaces tidy—it is about preventing accidents, reducing health risks for workers, and complying with current regulations. In this article, we will explore the importance of industrial cleaning for workplace safety, the relevant regulations, and the best strategies and equipment for ensuring a safe environment.

The importance of industrial cleaning for workplace safety

Industrial cleaning is about more than just hygiene—it is a fundamental aspect of workplace safety. A well-maintained and organized work environment significantly reduces the risk of slips, falls, and injuries caused by accumulated dirt, debris, or hazardous substances. Beyond reducing workplace hazards, a clean environment promotes better health for employees and enhances overall productivity.

Regulations and requirements for workplace safety in industrial cleaning

In Italy, workplace safety is regulated by Legislative Decree 81/08, which establishes the preventive and protective measures to be adopted in all work environments, including industrial cleaning operations. The D.Lgs. 81/08 mandates that workspaces must be maintained in safe conditions to prevent risks to the health and safety of workers, including cleaning staff. The primary responsibility for workplace safety lies on the employer, who must ensure a safe environment, provide adequate training, equip workers with personal protective equipment (PPE), and implement preventive measures against specific risks. These risks include exposure to chemicals and the possibility of accidental collisions, which are particularly relevant in industrial cleaning.

What should cleaning staff do to ensure safety?

Cleaning staff must strictly follow safety procedures, properly use personal protective equipment (PPE), and promptly report any potential hazards. Additionally, they must receive proper training on the safe use of equipment and the handling of chemical products. Employers are responsible for ensuring that cleaning staff have access to continuous and appropriate training to prevent workplace injuries and occupational illnesses related to cleaning operations.

Key risk factors when using industrial cleaning machines

Industrial cleaning machines, such as floor scrubbers and sweepers, are essential for maintaining cleanliness efficiently. However, improper use can lead to safety hazards for operators. Key risks include:

- Crushing and collision hazards: machines in motion, particularly in tight spaces or during reverse maneuvers, can cause injuries.

- Chemical exposure risks: cleaning agents and detergents may cause skin irritation, respiratory issues, or allergic reactions if not handled correctly.

- Slip and fall hazards: wet or slippery surfaces, often due to improper machine operation or insufficient drying time, increase the risk of workplace accidents.

- Ergonomic risks: poor posture, repetitive movements, and excessive strain while operating equipment can lead to musculoskeletal issues.

To mitigate these risks, regular machine maintenance, proper operator training, and strict adherence to safety protocols are essential.

How to minimize risks when using industrial cleaning machines

Ensuring the safe operation of industrial cleaning machines requires more than just preventive measures, it also involves selecting technologies designed to enhance safety. Based on Comac’s expertise with industrial scrubber dryers and sweepers, the following insights offer practical guidance on reducing potential hazards. Implementing these best practices can significantly improve workplace safety in industrial cleaning, lower the risk of accidents, and create a safer, more efficient work environment.

Preventing the risk of crushing and collisions

Ensuring that operators are properly trained in the safe use of cleaning machines is crucial, particularly when maneuvering in confined spaces or reversing. To enhance workplace safety during cleaning operations, most Comac machines are equipped with front and rear LED lights, available as standard or optional features. Additionally, flashing beacons alert others to the machine’s movement, while reverse buzzers provide an audible warning to help prevent accidents. Beyond Comac machines, incorporating visual and acoustic safety signals—such as warning lights and reverse alarms—can significantly enhance workplace safety in industrial cleaning. Clearly marking work zones and educating personnel on the presence of moving equipment further reduces the risk of accidents, promoting a safer and more efficient working environment.

Reducing chemical risks

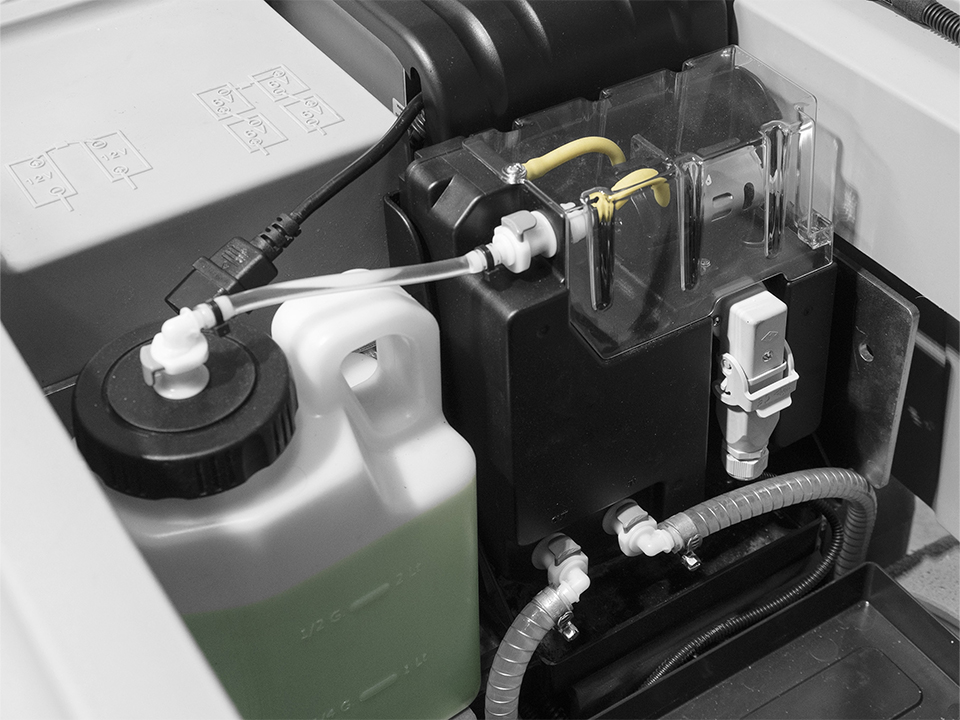

To minimize exposure to chemicals used in industrial cleaning, it’s crucial to implement automatic dosing systems, such as the CDS – Comac Dosing System, which help limit direct contact with hazardous substances. Operators should always wear gloves, protective eyewear, and masks when required by the product safety data sheets. Additionally, ensuring adequate ventilation in confined spaces is essential to maintaining a safe and healthy work environment.

Preventing falls and slips

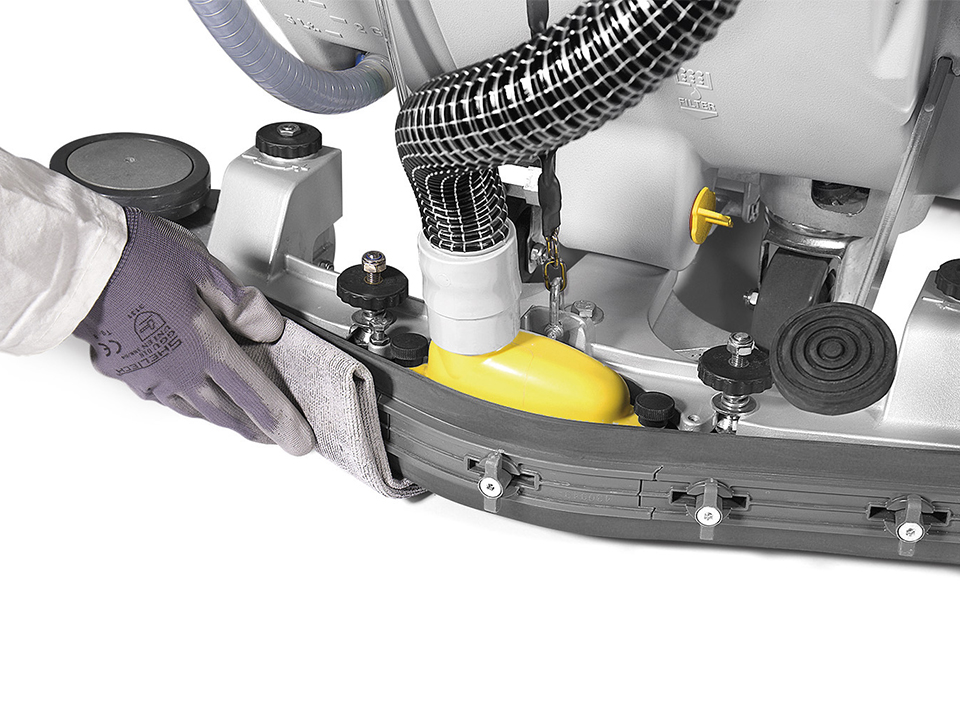

Industrial floor scrubbers are designed to leave surfaces clean and thoroughly dry. However, if not used properly, floors can remain overly wet, making them slippery and hazardous. To ensure effective drying, it’s crucial to regularly clean the machine and inspect the squeegee and squeegee blades for wear, replacing them when necessary. For more details, you can check out this useful guide on maintaining squeegee blades. Additionally, maintaining the proper cleaning of the floor scrubber ensures optimal performance and prevents malfunctions that could affect the drying process. This post offers practical tips for properly cleaning your floor scrubber. To further minimize the risk of falls and slips, be sure to clearly mark wet areas with appropriate warning signs.

Preventing ergonomic risks

Industrial cleaning machines should be designed to minimize physical strain on operators and enhance comfort during use. Ergonomics plays a crucial role: intuitive controls, adjustable seats on ride-on machines, and ergonomic handles on walk-behind models help prevent harmful repetitive movements. Furthermore, proper training on maintaining good posture and alternating tasks can significantly reduce ergonomic risks. For an in-depth look at the ergonomics of floor scrubbers, we recommend reading out our dedicated post.

Choosing the right cleaning equipment for enhanced safety

Selecting the right equipment for professional industrial floor cleaning not only boosts operational efficiency but also plays a crucial role in creating a safer work environment. Machines equipped with advanced technologies, integrated safety features, and ergonomic designs help reduce risks for operators and prevent accidents. For instance, Comac floor scrubbers and industrial sweepers are engineered with cutting-edge solutions that prioritize workplace safety while delivering exceptional performance.

How to choose the safest floor scrubber

To maximize safety during cleaning operations, it’s essential to select professional equipment like a floor scrubber equipped with intuitive controls, innovative technologies, and advanced safety features.

Comac’s C industrial floor scrubbers, including the C75, C85, and C100 models, combine cutting-edge technology with enhanced safety. They feature user-friendly controls, excellent visibility, and advanced safety solutions. For instance, the Bright configuration includes a rear camera, allowing operators to easily spot obstacles when reversing, significantly improving safety during maneuvers.

To further increase protection, an optional anti-collision sensor can be added to the rear of the machine, reducing the risk of accidental impacts. Additionally, the Blue Safety Spotlight system enhances the visibility of the floor scrubber, making it easier to spot in busy work environments and helping to minimize the risk of accidents.

How to choose the safest industrial sweeper

Industrial sweepers play a crucial role in maintaining safety and efficiency in large spaces or environments with significant dust and debris. Models such as the Comac CS60 and CS700 are specifically designed to address these needs by blending advanced safety features, user-friendly operation, and exceptional performance. Both models offer intuitive controls, allowing operators to easily and safely handle the machines, even during extended work periods. Moreover, they are equipped with powerful LED headlights, enhancing visibility during cleaning tasks in low-light conditions, which further improves operational safety. With these features and other integrated safety solutions, the CS60 and CS700 are excellent choices for creating safer and more efficient work environments.

Enhance workplace safety with advanced industrial cleaning solutions

As we’ve discussed, industrial cleaning and workplace safety are closely linked and crucial for maintaining a secure work environment and efficient operations. Selecting professional equipment, like Comac sweepers and floor scrubbers, equipped with innovative technologies and safety-focused features, is the key to reducing risks and improving overall efficiency. If you want to maximize your equipment’s potential and ensure your workplace is both safe and compliant with regulations, feel free to reach out to us. Our authorized dealers are available to offer tailored advice to help optimize your industrial cleaning processes and maintain the highest safety standards.

This post is also available in: Italian