In industrial and commercial environments, where every minute has a direct impact on productivity, choosing the right floor scrubber is a decision that affects operating costs, cleaning quality and service continuity. Selecting a professional floor scrubber dryer does not simply mean purchasing a machine, but identifying the solution that ensures high hygiene standards, reduced downtime and effective surface management.

The market offers many alternatives, which is why a common question arises among facility managers, purchasing managers, and cleaning companies: which floor scrubber should you choose? In this guide, we analyze the key factors that influence the decision, compare the different types available and define the criteria that turn this investment into a real operational advantage.

Table of Contents

- What are floor scrubbers and how do they work

- What are the advantages compared to manual cleaning

- When is the right time to use a professional floor scrubber

- Which type of floor scrubber should you choose

- The key parameters for choosing the right floor scrubber

- Best-selling Comac floor scrubbers

- Frequently asked questions

What are floor scrubbers and how do they work

Floor scrubbers are professional machines designed to wash and dry floors in a single pass, making it possible to maintain a constant level of hygiene even in highly frequented environments. Their widespread use is the result of an evolution that, as described by Giulio Guizzi in the book Pulizia igienica e sanificazione, transformed completely manual cleaning methods into increasingly organized, technology-supported processes.

Over time, cleaning evolved from simple brooms and cloths to more efficient systems, eventually leading to modern machines. Dedicated brushes, specific detergents and pressure washers marked the first stages of this journey, which finds one of its most advanced results in scrubber dryers.

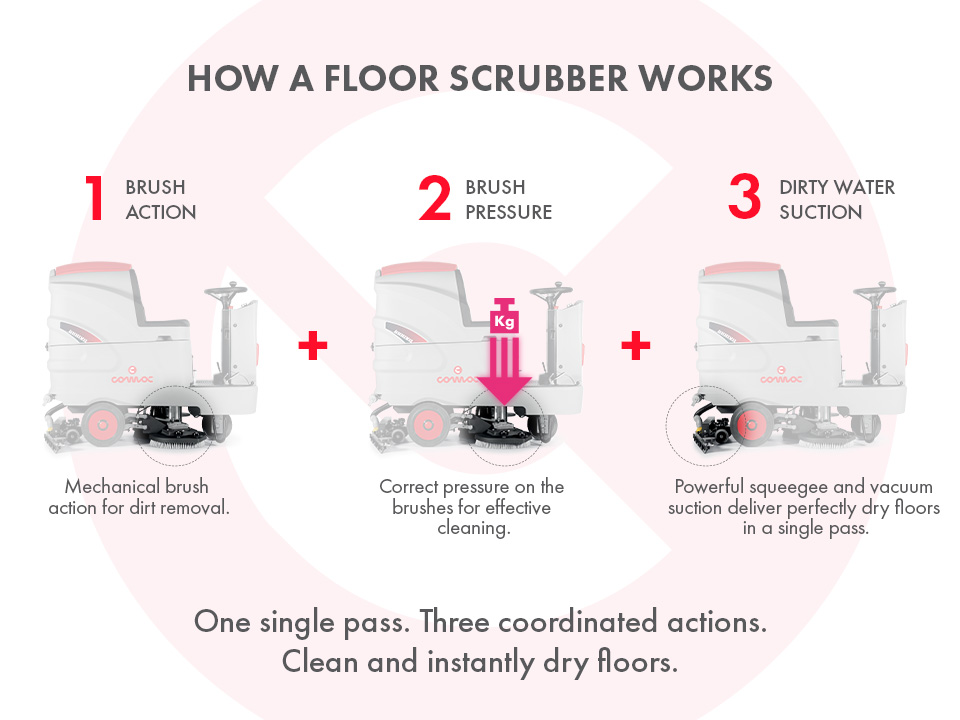

Modern floor scrubbers combine three essential functions: the mechanical action of the brushes, the correct pressure applied to the floor, and the suction of dirty water through the squeegee and vacuum motor. It is this coordination that guarantees uniform cleaning results and floors that are immediately dry. If you would like to explore each phase of the process in greater technical detail, a dedicated guide explaining how a scrubber dryer works is available on our blog.

What are the advantages compared to manual cleaning?

Compared to traditional mop-and-bucket methods, a professional floor scrubber delivers deeper, more uniform and faster cleaning results. The mechanical action of the brushes combined with the immediate suction of dirty water reduces cleaning time, physical effort and waste, ensuring safer surfaces and consistent hygiene even in high-traffic environments.

| Manual cleaning with traditional methods | Mechanized cleaning with professional floor scrubbers |

|---|---|

| Long cleaning times, especially on medium and large surfaces | Fast coverage of even very large areas |

| Inconsistent and uneven results | Uniform and easily repeatable cleaning results |

| Higher risk of cross-contamination | Dirt removed and vacuumed in a single pass |

| Floors remain wet for several minutes | Floors left immediately dry and safer |

| High physical effort for the operator | Significant reduction in operator fatigue |

| Water and detergent consumption difficult to control | Optimized, monitored and therefore more sustainable consumption |

When is it time to switch to a professional floor scrubber?

Knowing when to introduce a professional floor scrubber into your business or facility means understanding the limits of manual cleaning methods and evaluating the real operational needs of your spaces. Today, cleaning is no longer just an operating cost, but a strategic factor that directly affects safety, the appearance of facilities and overall efficiency. For this reason, a professional floor scrubber becomes the ideal solution when a consistent, controlled and high-performance cleaning process is required beyond what traditional mops and manual tools can provide.

A professional floor scrubber stops being an option and becomes a necessity when these signs appear:

- Time becomes a significant cost. When staff spend many hours cleaning areas larger than 100–300 sqm, the impact on costs and core activities increases. Mechanized cleaning allows you to save time, reduce labor costs and perform more frequent cleaning without taking resources away from primary operations.

- Cleaning must be continuous. In high-traffic environments such as retail stores, gyms, cafeterias, production departments and common areas, dirt builds up quickly. A floor scrubber restores hygiene in just a few minutes and allows multiple daily cleaning cycles, keeping floors consistently safe and presentable.

- Manual results are never uniform. Streaks, marks and uneven cleanliness are typical limits of manual cleaning. The combined action of brushes, pressure and suction ensures a deep, uniform, and repeatable cleaning result across the entire surface.

- Certified standards are required. When compliance with hygiene regulations such as HACCP or internal quality protocols is mandatory, human variability becomes a limitation. A professional floor scrubber guarantees a controlled, traceable process that meets required standards consistently.

Which type of floor scrubber should you choose?

Once you have established the need for a professional machine, the next step is to understand which floor scrubber to choose among the available solutions. Each type is designed to meet specific operational needs related to space, type of dirt, and cleaning frequency. For a complete overview, you can explore the full range of Comac floor scrubbers on our website.

The main categories are:

- Walk-behind floor scrubbers, ideal for small or complex areas.

- Ride-on floor scrubbers, designed for large surfaces requiring high productivity.

Floor scrubbers can also be classified based on the type of brush system and scrub deck:

- Professional roller brush floor scrubbers, equipped with cylindrical brushes and perfect for removing small debris during washing.

- Disc brush floor scrubbers, ideal for smooth floors and for most commercial and industrial environments.

Choosing the right type ensures optimal performance and more efficient management of cleaning time.

Walk-behind floor scrubbers

Walk-behind floor scrubbers are machines operated on foot, with the operator walking behind and guiding the machine using the handle. They are the ideal solution for small or complex areas where compact size and high maneuverability are essential, such as retail stores, gyms, offices, and high-traffic walkways.

Ride-on floor scrubbers

Ride-on floor scrubbers allow the operator to work while seated, ensuring greater comfort, higher productivity, and optimal management of medium to large surfaces. This configuration is ideal for environments such as logistics, industrial facilities, large-scale retail and any setting that requires continuous cleaning operations over wide areas.

Cylindrical brush floor scrubbers

Cylindrical brush floor scrubbers use rotating cylindrical brushes that provide a more aggressive cleaning action compared to disc brush systems. They are particularly effective for removing small debris during the washing process and for cleaning structured surfaces such as anti-slip floors, rough porcelain stoneware or production areas with heavy-duty dirt.

Disc brush floor scrubbers

Disc brush floor scrubbers are the most widely used and versatile solution in the professional cleaning industry. They operate with one or two circular brushes that work evenly across the surface, ensuring excellent cleaning performance especially on smooth floors such as porcelain tile, treated concrete, resin, or PVC. They are suitable for most commercial and industrial environments, as they offer the ideal balance between ease of use, reduced consumption and consistent results.

Key parameters for choosing the right floor scrubber

The most effective floor scrubber is not necessarily the largest or the most powerful, but the one that matches the operational needs of your environment. To configure the solution that best fits your facility, evaluate these four essential factors:

- The cleaning area: surface size and layout. Square meters are the starting point. For confined or cluttered spaces with obstacles such as shelves, machinery or furniture, the agility of a walk-behind model is unbeatable. For large, open areas where speed is crucial, the hourly productivity of a ride-on machine becomes the strategic choice to optimize cleaning time.

- The challenge to overcome: type of dirt and hygiene requirements. What kind of dirt do you face every day? Light dust and footprints in a commercial area require a very different action than oily residues or grease in a workshop. The choice of power level, brushes and accessories depends on the nature of the soil. Similarly, is the goal basic visual cleaning or deep sanitation to comply with standards such as HACCP? The required hygiene level determines the most suitable technology.

- The pace of work: frequency and duration of cleaning operations. Will the machine be used for one hour per day or for a full eight-hour shift? Intensive, prolonged use requires not only robustness and reliability, but also careful attention to ergonomics and operator comfort to maintain high performance and reduce fatigue.

- The power source: battery or corded operation? Do you need complete freedom of movement, covering large areas or multiple zones without interruptions? Battery-powered models are the ideal answer. If, instead, cleaning is confined to a smaller area and unlimited runtime is a priority, the continuous power of a corded machine can be the optimal solution.

Best-selling Comac floor scrubbers

To make it easier to choose among the many models and configurations available, it is helpful to know some of the most popular and best-selling Comac floor scrubbers.

Vispa 35

Vispa 35 is a compact and easy-to-manoeuvre walk-behind floor scrubber, ideal for small or highly congested areas. It is available with either disc brushes or cylindrical rollers, allowing you to match the machine to the floor type and level of dirt. Its agility makes it perfect for shops, gyms, offices and high-traffic areas where quick interventions are needed without disrupting ongoing activities.

Antea

Antea is a versatile and robust walk-behind floor scrubber, suitable for most professional environments. The range includes disc versions, a cylindrical roller version (BTS), and an orbital version (BTO), offering complete coverage for different needs: from daily cleaning in shops and public spaces to the removal of heavier dirt in industrial settings. Thanks to its reliability and ease of use, it is one of the most popular models among cleaning companies and facility managers.

Innova

Innova is a ride-on floor scrubber designed to deliver high productivity and maximum operator comfort. It is available with either a disc deck or cylindrical brushes, allowing it to meet both routine maintenance needs and more intensive cleaning on textured surfaces. The sit-on driving position, combined with long operating autonomy, makes it ideal for large areas such as warehouses, production departments, and shopping centers.

C120

C120 is a ride-on industrial floor scrubber designed for intensive applications and very large areas. It combines a cylindrical pre-sweeping unit, ideal for collecting debris and solid dirt, with a disc scrubbing deck that delivers deep and uniform cleaning results. This hybrid configuration allows multiple operations to be carried out in a single pass, significantly reducing intervention times in the most demanding environments.

How to choose the most suitable professional floor scrubber with Comac’s support

If you are still evaluating which scrubber dryer to choose and would like to speak with a specialist, the Comac team is ready to assess your environment and recommend the most effective solution. Contact us: selecting the right floor scrubber becomes much easier when you can rely on expert technical support and a recommendation based on the real needs of your facility.

Frequently asked question

The maintenance costs of a floor scrubber depend mainly on the intensity of use and the specific model, but generally include the periodic replacement of brushes or rollers, squeegee blades, filters and, for battery-powered machines, the batteries themselves. Proper routine maintenance helps reduce running costs and prevents more expensive failures over time. Consumables such as brushes and squeegee blades have a variable lifespan depending on the type of floor and how frequently the machine is used. However, they represent a relatively small investment compared to the productivity gains achieved versus manual cleaning. Using original spare parts and scheduling regular inspections helps maintain high performance and extend the machine’s operational life.

Yes, in most cases the same floor scrubber can be used on different types of surfaces, including porcelain stoneware, resin, treated concrete, PVC and industrial flooring. The key factor is selecting the brushes and accessories that are best suited to each floor type. For wooden floors or particularly delicate surfaces, it is advisable to use a machine with precise pressure control and appropriate detergents, while avoiding excessive amounts of water to prevent damage to the material.

The type of detergent depends on the level of dirt and the surface, but it is essential to choose products specifically formulated for floor scrubbers. These detergents prevent foam formation and ensure effective cleaning without damaging the machine.

Alongside traditional detergents, there are low-environmental-impact options such as concentrated products or formulations made with eco-compatible ingredients, which help reduce consumption and chemical residues. Technology can also play a key role in making cleaning more sustainable. Systems like Comac ReWater, which enable the reuse of wastewater, drastically reduce both water usage and chemical consumption, improving overall efficiency while lowering the environmental impact of cleaning operations.

This post is also available in: Italian