You would not say it, but squeegee blades are a very important component of your floor scrubber. This is because the right combination of squeegee assembly, blades and vacuum power is what allows you to have excellent drying and therefore cleaning results. For this reason we believe it is essential to have the ultimate guide to squeegee blades of your floor scrubber, which will provide you with clear and useful information.

Squeegee assembly: what it is and how it works

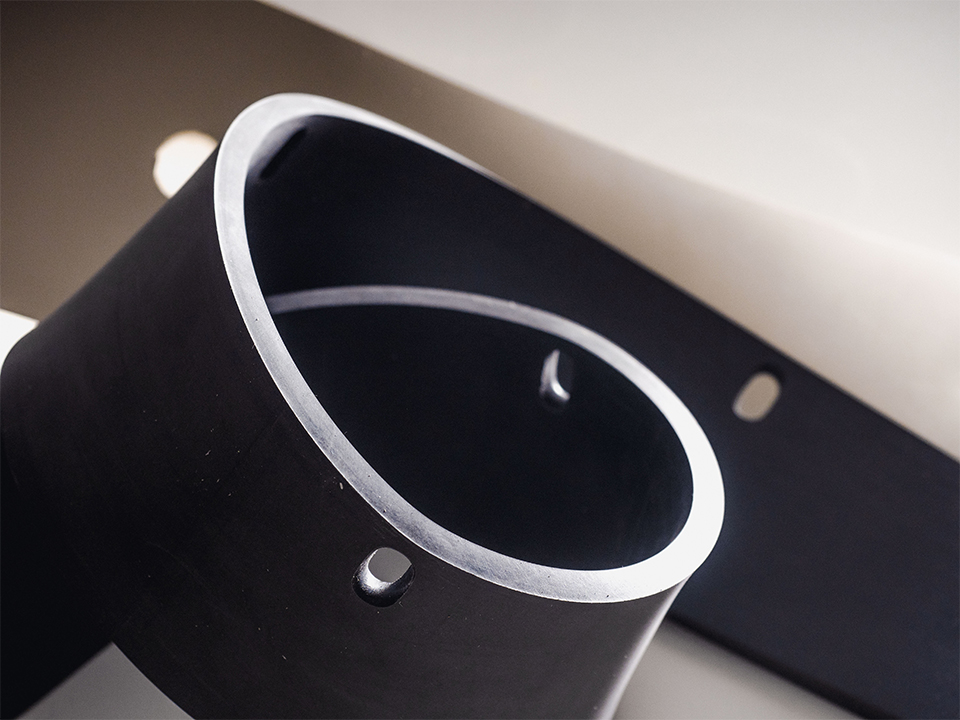

As always, let’s start from the basics with this guide to squeegee blades. The squeegee assembly is a component of the floor scrubber that consists of a rigid body that is longer than the brush head. This is because the squeegee must channel the solution dispensed by the brushes towards the central recovery point, where both the solution and the dirt present on the floor are sucked up.

The squeegee assembly of a floor scrubber consists of two squeegee rubbers, which are often called blades:

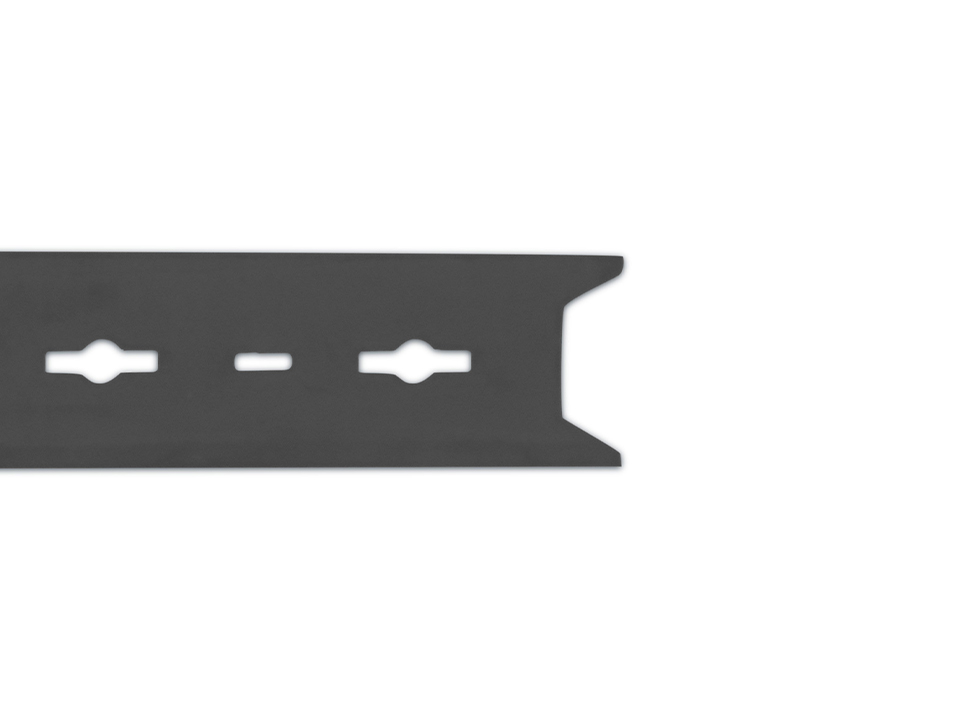

- The front squeegee blade with small slots. It has the task of bringing the water towards the center, and thanks to the slots towards the rear blade.

- The rear squeegee blade. It adheres perfectly to the floor, creating a sort watertight seal that ensures excellent drying.

There may also be other reinforcement blades that help to create a vacuum chamber to convey the solution and dirt towards the point of maximum suction. To obtain this “watertight” effect it is important to adapt the squeegee to the conditions of the floor by adjusting it in a proper way and choosing the correct type of blades.

Types of squeegee blades

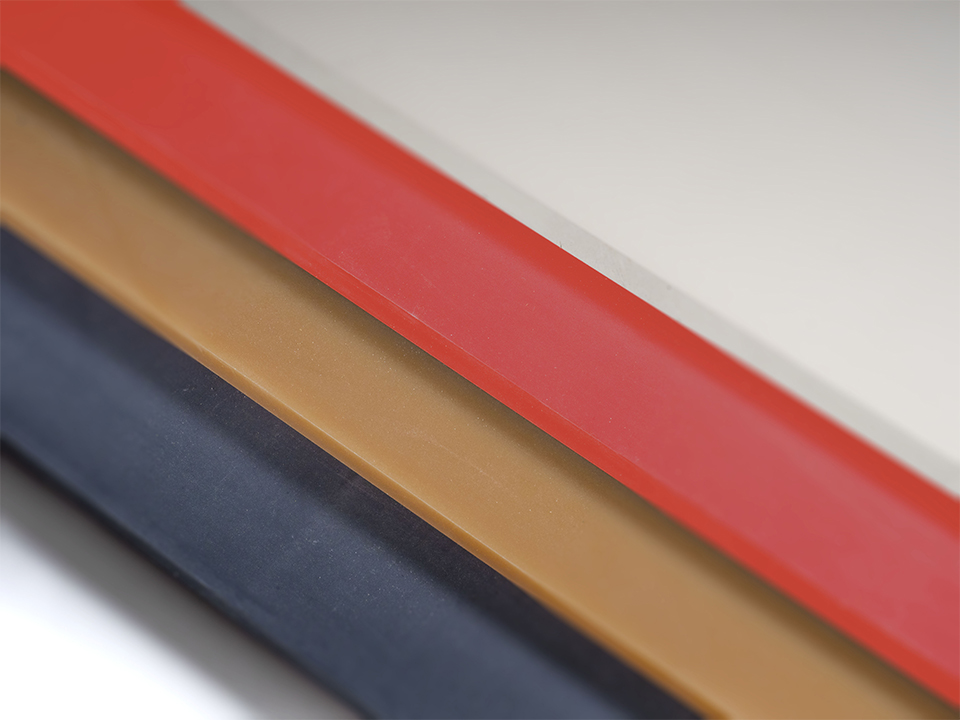

The main goal of this guide to squeegee blades is to provide you with all the information you may need to choose the right ones for the floor and the dirt that has to be cleaned. In fact, there are different types of squeegee blades materials in the floor scrubbers market. Let’s see the most known and used materials:

- Natural rubber (also called para rubber)

- Latex

- Polyurethane

- TOVO

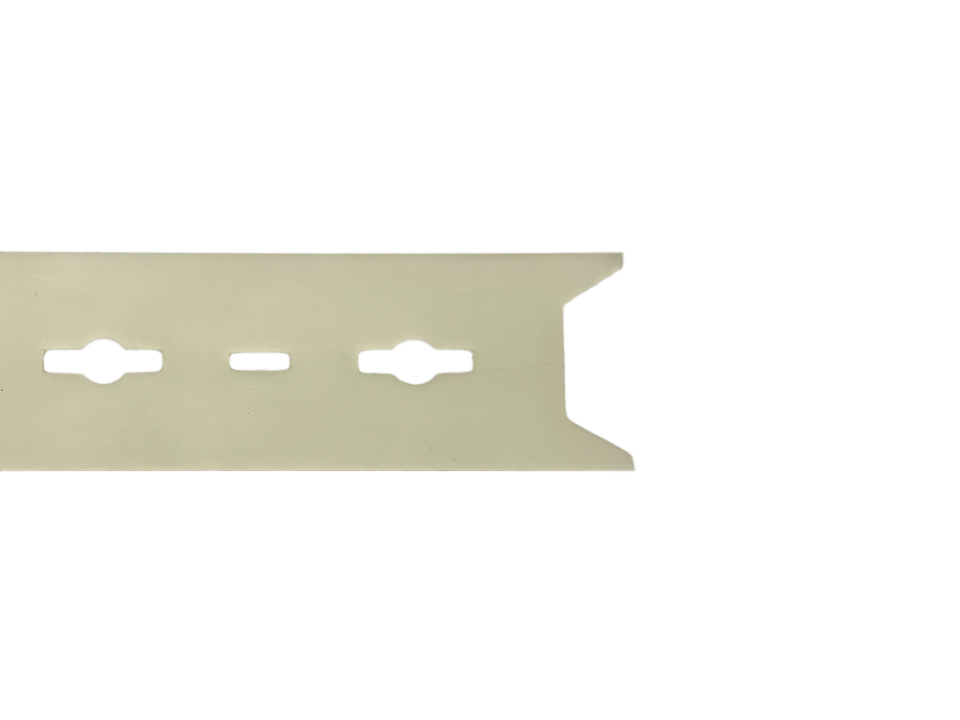

Natural rubber squeegee blades

Natural rubber squeegee blades are made from high temperature processing of natural materials combined with resinous materials. They are soft blades and therefore perfect for smooth, uniform floors and tile floors with grout lines. This is why they are often used in hospitals, shopping centers and public environments such as airports and train stations. The natural rubber makes these blades very flexible and therefore they perfectly adhere to the surface. However, they must not be used for the collection of oily material as the natural rubber absorbs it causing the blade to lose its shape, and therefore its suction power. This is the standard material chosen for Comac scrubbing machines.

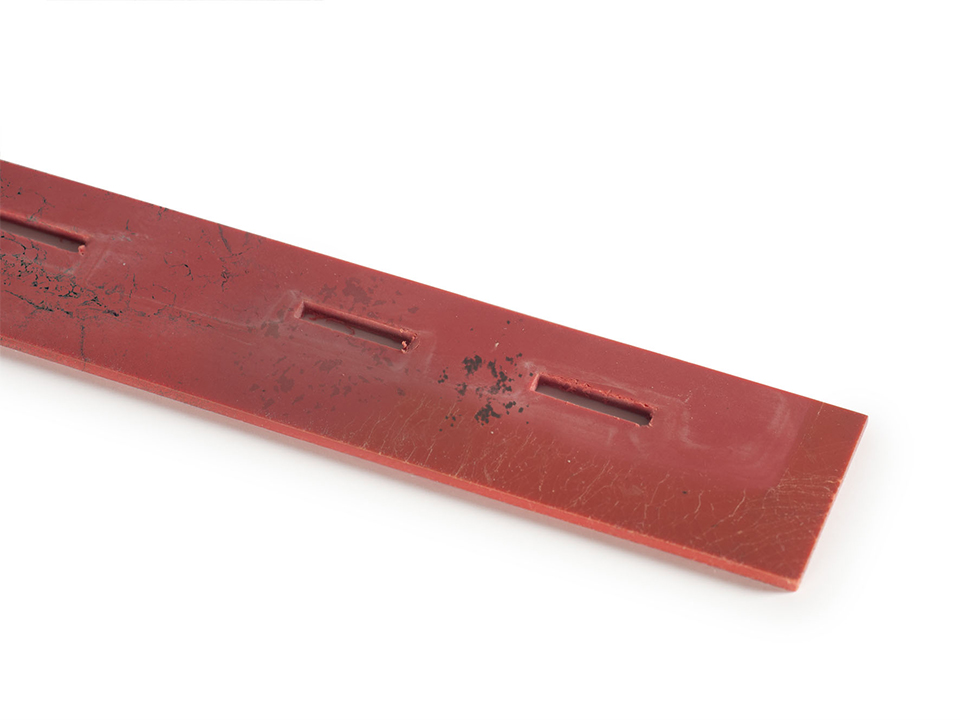

Latex squeegee blades

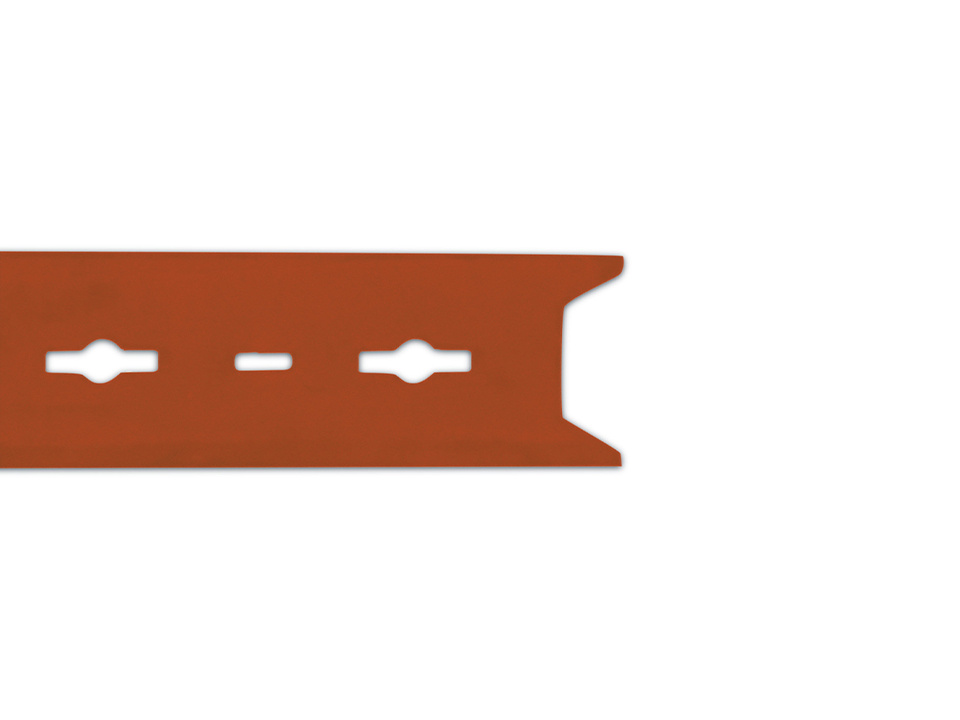

The rubber of these blades comes from a much more refined processing of the precious part of the rubber which is combined with chemical elements designed to improve its mechanical performance. The percentage of rubber present in the latex blades is higher than that present in the natural ones. They are usually characterized by a pink red color and their greater resistance to abrasion and chemical agents. This makes them suitable for almost all applications but not in the presence of oily dirt since, as happens with natural rubber, it would be absorbed, thus damaging the shape of the blade. Latex rubbers can work well on industrial or concrete floors, even if they are rough or with large grout lines.

Polyurethane squeegee blades

Polyurethane blades, also called urethane, are composed of a synthetic rubber compound that derives from a family of polymers whose chain is made up of urethane links. The polyurethane blades are particularly resistant to chemicals and heavy dirt, and therefore suitable for cleaning industrial oils and greases. Unlike natural or latex blades, polyurethane blades do not absorb oils and are perfect for use in the automotive and food sectors. In addition, they can work well on any surface, even those that are uneven or with grout lines.

TOVO squeegee blades

TOVO is an industrial rubber particularly suitable for situations where there are oils and detergents on the floor. These blades have a high resistance to the action of hydrocarbons, solvents and greases. Moreover, they are also able to withstand temperatures up to 160°C.

How to improve the performance of the squeegee blades: some tips

In the last part of this guide to squeegee blades we want to give you some tips regarding this floor scrubber component that will help you improve the cleaning performance. In fact, the squeegee assembly and the squeegee blades are the elements that finish the cleaning task of the floor scrubber itself. Blades are therefore decisive in the quality of the result and for this reason we want give you some tips.

Choose the right squeegee blade. So, carefully evaluate the type of dirt and the type of floor before choosing the blade for your scrubbing machine.

Check the wear of the blade. Especially if the floor scrubber is used by several people, remember to check it before you start. And don’t forget that for Comac scrubbing machines the blades can be used on all 4 sides, so rotate them before replacing them.

Buy OEM squeegee blades. When you need to replace the blades, always choose original spare parts suitable for the model of your floor scrubber.

Clean the blades after each use. When you clean the floor scrubber at the end of the cleaning shift, also remember its blades. In this way you avoid that any residues do not allow it to dry the floor well.

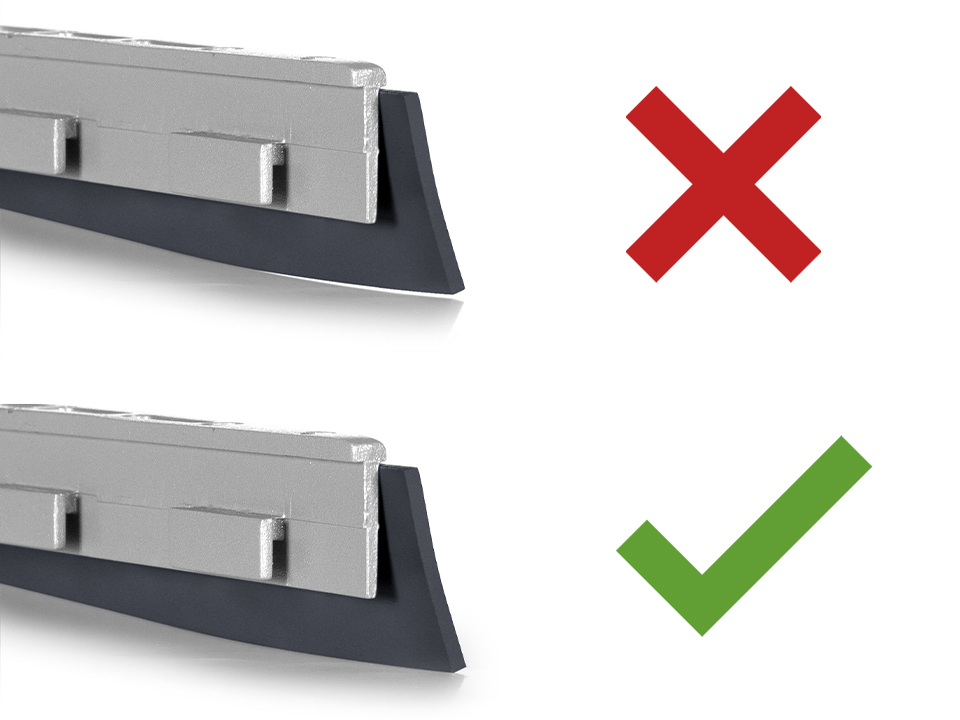

Adjust the squeegee. Make sure there is even pressure across the squeegee blade and adjust the squeegee assembly if necessary. This is one of the floor scrubbers hacks that allow you to optimize the drying performance. If you do not know how to adjust the squeegee, have a look at the use and maintenance manual of your scrubber dryer.

Check the squeegee assembly. In fact, if the squeegee has suffered a strong impact it could be bent, deformed or damaged, and therefore not dry well regardless of the blade you have chosen. Comac scrubbing machines equipped with automatic squeegee uncoupling, such as Antea or Innova, help prevent this issue.

Clean, dry and safe floors: it all starts with the squeegee blades

You may have noticed that squeegee blades are a crucial component of any floor scrubber, as they ensure clean, dry and—most importantly—safe floors. If the blades are not cleaned regularly, or worse, if they are worn out, your machine won’t dry properly, leaving water streaks and wet surfaces that negatively affect the overall cleaning results.

That’s why it’s essential to choose the right type of blade, check its condition, and correctly adjust the squeegee. These small actions can lead to better performance, less effort, lower costs, and improved safety for everyone.

If you need help selecting or maintaining your squeegee blades, Comac’s network of authorized dealers is always available to support you and help you find the most suitable solution for your professional cleaning needs. Contact us!

This post is also available in: Italian